Can the concrete breathe?

We are aware of the fundamental problems of today’s world: Hunger, war, terrorism, pollution of the environment, and climate warming. In the face of so many threats caused mainly by human over-exploitation, each of us should take responsibility for our planet and try to protect it.

In the field of architecture and construction, the challenge for today’s architects, urban planners, and builders is to design a functional, modern, and, at the same time, environmentally friendly space, where the meaning of the words “sustainable development” is fully met. Eco-design has become a kind of indicator of the sensitivity and taste of the designer.

Urban development should be subject to strictly sustainable development in the social, environmental, and structural fields. The prospect of a global environmental crisis and the growing awareness of human responsibility is leading to the implementation of increasingly recent solutions to halt disaster.

One of the many components of the environmental crisis is the significantly increasing air pollution. It is particularly evident in urban areas where concentrations of fine particles PMx, nitrogen oxides (NOx), and volatile organic compounds (VOC) are significantly exceeded. A mixture of these compounds combined with solar radiation causes photochemical smog, which is very dangerous to humans and plants. Concrete with the addition of TiO2. So far, ad hoc measures only partially address the problem of deteriorating air quality.

To improve it, we are increasingly seeking customized solutions (reducing traffic in city centers by isolating special zones or even closing streets or implementing additional traffic charges) to improve its quality.

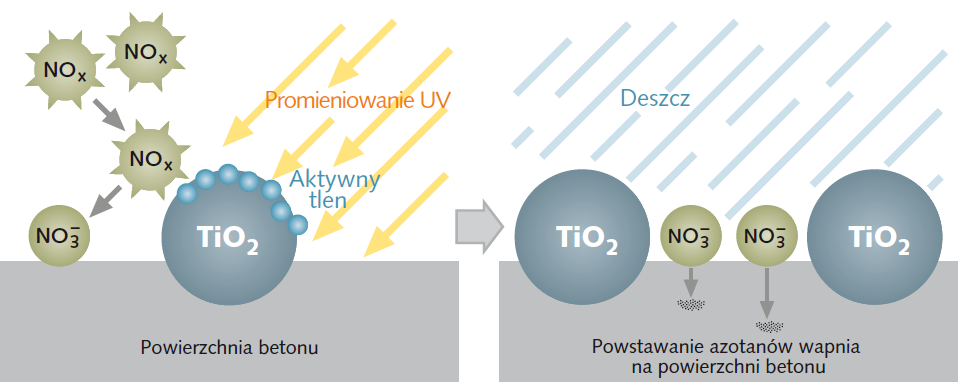

A very common way to combat smog, which has been successfully applied by Western architects for years, and which has become popular in Poland recently, is to create projects, both urban and structural, with photocatalytic properties. They can be obtained by using the basic building block of concrete with the addition of a nano-TiO2 titanium dioxide, which is an addition to an engineered concrete mix. This substance accelerates the natural distribution of pollutants by sunlight (UV-a radiation). The production of nanoparticles gives TiO2 properties that can be used effectively in the photocatalytic oxidation process on concrete products. Sunlight (UV-a radiation with a wavelength < 410 nm) is sufficient to activate this process. The TiO2 particle thus induced is transformed to form hydroxyl radicals (OH•) and active oxygen (superoxide anion radical O2) with highly oxidative properties on its surface. As the resulting compounds are very reactive, they are rapidly changing, reacting with organic and inorganic substances.

The newly formed products are then neutralized by the concrete components. The result of the whole process is harmless compounds that do not pose a risk to humans and the environment. A very important feature of the photocatalyst (TiO2) is that, despite taking part in the reactions involved, it remains unchanged in quantity and chemical form. This ensures that the ongoing process is sustainable and constantly renewable. The photocatalytic surface obtained from concrete components, under the influence of sunlight, gains the ability to absorb NOx oxides and oxidize them to NO3 nitrogen ions. These ions then react on the surface of the concrete with [Ca(OH)2] [ca(OH)2], finally forming environmentally safe salts (calcium nitrates) which are rinsed off by atmospheric precipitation.

Self-cleaning with TiO2

The use of a photocatalyst in the manufacture of concrete components, in addition to the properties of the air cleaner from gaseous pollutants, allows them to maintain the original appearance of the surface. The ability to self-clean also results from the other properties of TiO2. This results in a change in the wetting angle of the surface of the photocatalyst under the influence of UV radiation, which decreases almost to zero. This makes rain droplets on the concrete surface produce a thin water film to facilitate the removal of impurities. This solution is particularly important in construction sites operating in high-traffic areas. Due to the reduction of air pollution and dirt on concrete surfaces, it can be used effectively to design concrete building facades, surfaces, and urban architecture elements.

This solution ideally responds to the growing demand for top-quality precast concrete that is capable of meeting modern design trends, space creation, and the drive for unique, environmentally friendly architecture. The technology of photocatalytic products manufacture does not change the basic characteristics of concrete in any way, nor does it affect its aesthetic characteristics. Designed components with unlimited shapes, rich colors, different finishing methods, and parameters that classify products as environmentally friendly are a unique offer for conscious risks and environmentally friendly design of architects and engineers.

The photocatalytic surface obtained in the concrete element, under the influence of sunlight, gains the ability to absorb NOx oxides and oxidize them into NO3 nitrogen ions. These ions then react on the surface of the concrete with calcium hydroxide to form the final environmentally safe salts.

Author: Jakub Suchorzewski